Clocks And Things

Preserving Time For Future Generations

The Bulova Accutron

•Bulova began developing the Accutron in 1952.

o The first electronic watch that was guaranteed accurate to within 2 seconds a day, or 1 minute a month.

o The secret behind this inherent accuracy will be a tuning fork which will divide each second into hundreds of equal parts.

o In 1959, Max Hetzel and William Bennett completed the development of the Accutron 214 at Bulova Headquarters in New York.

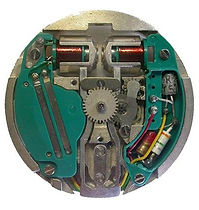

The Accutron 214

Departing sharply from traditional watches, an Accutron movement uses a transistorized oscillator to power a pair of electromagnetic drive coils. The coils act upon a magnetized tuning fork, whose alternating, vibrational motion is then directly converted into rotational motion by a microscopic jeweled ratcheting system known as an index mechanism. The most significant Accutron calibers oscillate at a rate of 360Hz, equivalent to a mechanical rate of 2.592Mbph. For comparison, quality 'hi beat' mechanical watch movements operate at a rate of 36kbph. The tuning fork's 360Hz vibrations also give an Accutron its characteristic humming sound and smooth sweep second motion.

The Accutron 218

While previous efforts had focused on refining the 214, the future of Accutron development would be characterized by multiple new movement calibers. In 1965, Bulova released the 218, a slimmer movement than the 214 (4.4mm vs 5.5mm), with a more traditional side-exiting setting stem. The 218 was released in a range of complications not seen in the 214, including calendar functions and a jump-hour secondary timezone variant. While the 218 was a reliable, widely adopted caliber, it was never offered in a true Spaceview variant, and never achieved the enduring popularity of the 214.

Index Wheel and Jewels

• The index wheel of a 218 movement is 2.40mm (0.095") in diameter and has 320 teeth, each of which is about 0.01mm high (0.0004") and 0.02mm (0.0008") wide.

• The index and pawl jewels are perfect little square blocks of synthetic ruby, 0.18mm (0.007") square and 0.06mm (0.002) thick.

• How these parts were manufactured has remained a closely-guarded secret.